Transforming the Future of Paint and Protective Coatings: A Strategic Collaboration between PT Krigsmann and PT Propan Raya ICC

In a groundbreaking partnership, PT Krigsmann and PT Propan Raya ICC have joined forces to revolutionize the paint and protective coatings industry. This collaboration leverages the cutting-edge technology and expertise of both companies to deliver unparalleled quality and innovation.

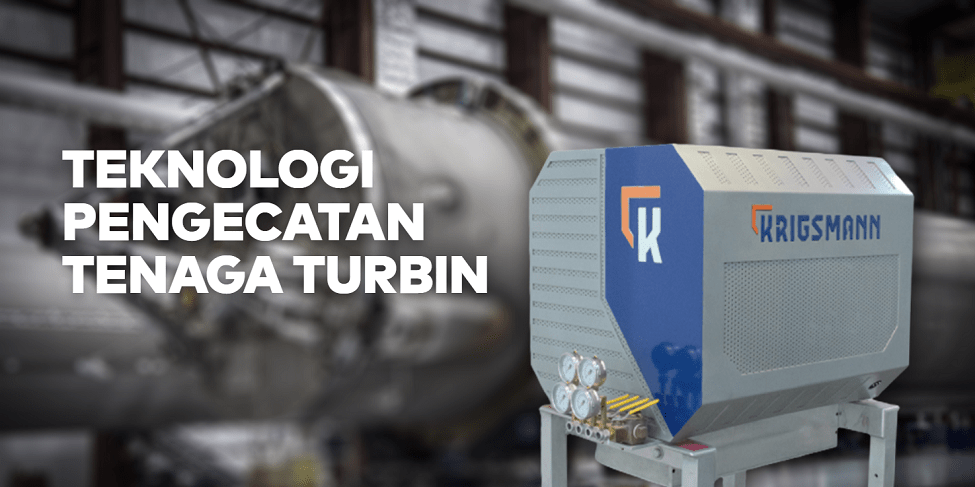

Pioneering Excellence in Paint Technology

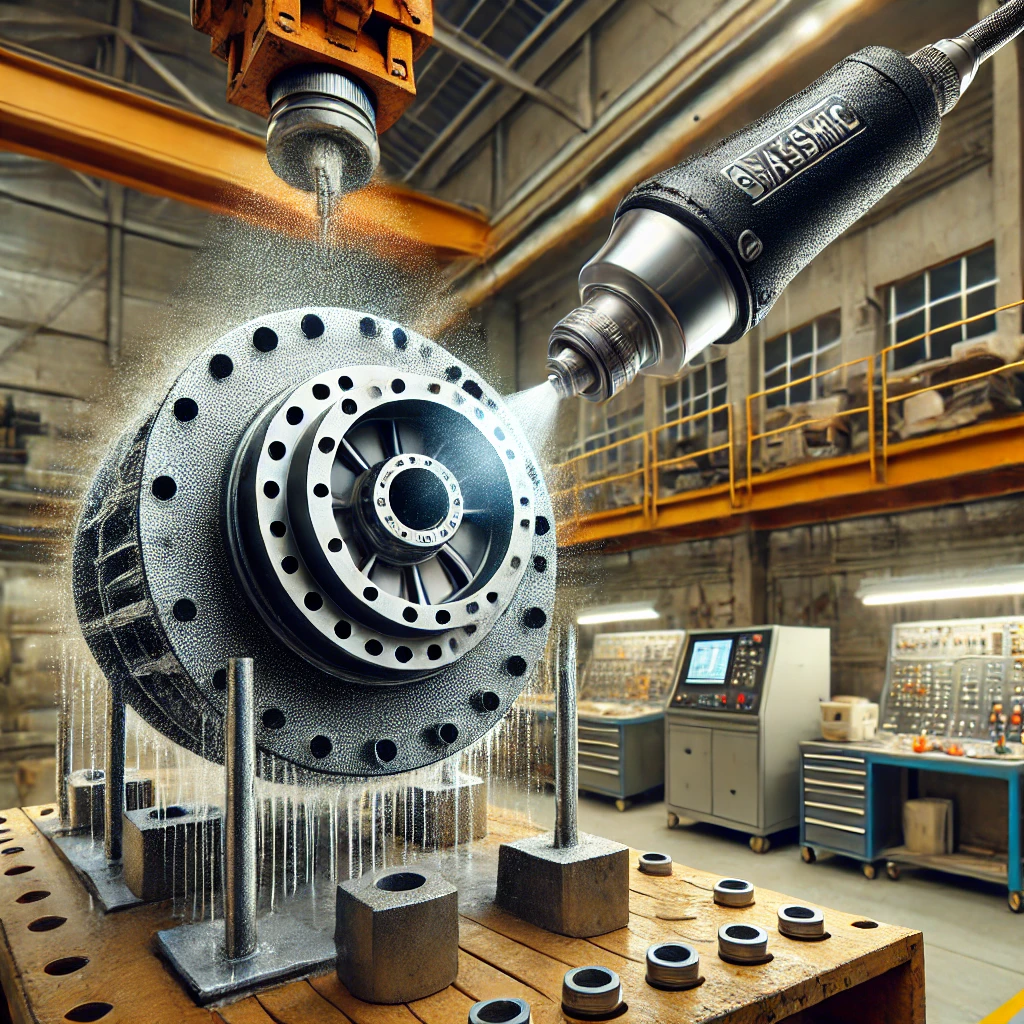

PT Krigsmann, renowned for its superior spray gun technology and commitment to innovation, brings decades of experience and a reputation for excellence to this collaboration. Their advanced spray systems are designed to optimize paint application, ensuring even coverage and exceptional finish quality.

Expertise in Protective Coatings

PT Propan Raya ICC, a leader in the development of high-performance coatings, adds their extensive knowledge and innovative product formulations to the mix. With a focus on durability and environmental sustainability, PT Propan Raya ICC’s coatings are engineered to withstand the toughest conditions while minimizing environmental impact.

Synergy for Superior Solutions

Together, PT Krigsmann and PT Propan Raya ICC are poised to set new standards in the paint and protective coatings industry. By combining PT Krigsmann’s state-of-the-art application technology with PT Propan Raya ICC’s advanced coating formulations, they aim to create products that not only meet but exceed industry expectations.

Benefits of the Collaboration

- Enhanced Performance: The fusion of advanced spray technology and high-performance coatings results in superior application efficiency and long-lasting protection.

- Innovative Products: Continuous research and development efforts will lead to the creation of innovative products that address the evolving needs of various industries.

- Sustainable Practices: Both companies are committed to sustainability, ensuring that the new product lines are environmentally friendly and comply with the highest safety standards.

- Customer-Centric Solutions: The collaboration focuses on delivering tailored solutions that meet the specific requirements of customers across different sectors, including automotive, industrial, marine, and construction.

A Vision for the Future

This partnership is not just about creating products; it’s about shaping the future of the paint and coatings industry. With a shared vision of excellence and innovation, PT Krigsmann and PT Propan Raya ICC are dedicated to providing customers with the best possible solutions, driving progress, and setting new benchmarks for quality and performance.

Stay tuned for the launch of our new range of paints and protective coatings, designed to transform your projects with unparalleled quality and reliability.